|

|

Build Your Online Product Catalogs?

| Product Name: |

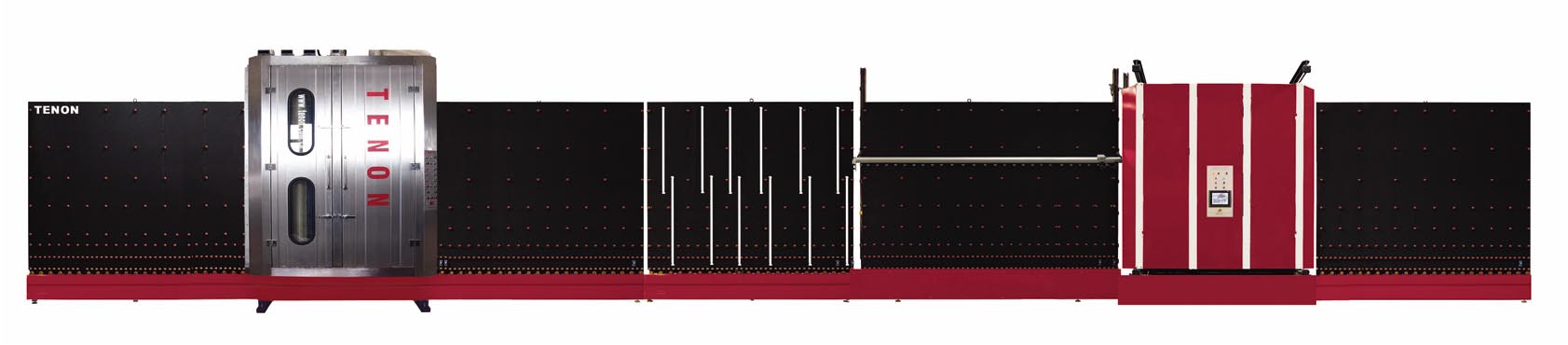

Automatic Insulating Glass Production Line

|

| Supply Ability: |

260sets I.G Line |

| Related proudcts |

double glazing glass, insulating glass, |

| Specifications |

TE-3LP-2500 |

| Price Term: |

FOB |

| Port of loading: |

Tianjin Port,China |

| Minimum Order |

1Set |

| Unit Price: |

USD72000.00/Set |

|

Vertical washing machine with its robust structure in stainless steel, is equipped with 3/4 pairs brushes with variable thicknesses from 3-12mm. Independent motors for each brush ensure the reliability of the wash and, in particular, the absence of vibrations. The life and uniformity of brushes are extended by rotating them 180

degrees to achieve uniform wear. Independent stainless steel tanks are provided for washing & rinse section in order to avoid the mixing of dirt and accelerate water filtering and recycling. An automatic shut down the air flow in case of conveyor belt stop. Low-E glass is ***ected at entry, the front hard brushes are then automatically excluded and washed with another 2/3 pairs Low-E brushes. Thanks to the front and rear stainless steel doors, machine access is easy and maintenance is reduced to a minimum.

After the glass come to the reference point the frame locator bar for the front leading edge and the bottom edge are tilting into position automatically. The adjustment shall be controlled by a centrally located adjustment wheel from 0-30mm and automatically adjusted different glass thickness. Back panel of conveyor shall be located visual inspection light so that checking the dirt on the glass surface by passing through.

Plate press box can be assemble and press double or triple glazed IG units. If the first glass comes into the box, the panel suspended suction cup holds the glass and waiting second glass mounted ***cer , is positioned and stabilized by means of an air cushion . The movable section automatically brings the first panel onto the second one, pressing them uniformly, automatically adapting pressure according to the size of panels. The press is

completely automated and controlled by a PLC. All functions can be operated from a touch screen panel located at the front side of the machine.

|

| Company: |

TENON (BEIJING) EQUIPMENT CO., LTD

|

| Contact: |

Mr. Robin Jiao |

| Address: |

No.3 Juhe Fifth Street,Jufuyuan Industrial Zone,Tongzhou, |

| Postcode: |

101127 |

| Tel: |

86 10 59416134 |

| Fax: |

86 10 80529297 |

| E-mail: |

|

|

|

|